In today’s competitive business landscape, having the right vehicle can make all the difference. Among these, the 16-foot truck stands out as a versatile solution tailored for various applications. Whether you’re in the food industry requiring temperature-controlled deliveries or in the culinary field seeking a mobile kitchen solution, understanding the diverse offerings of 16-foot trucks is crucial. This article dives deep into three vital categories of 16-foot trucks: the refrigerated box truck designed for safe and compliant food transport, the mobile deep fryer food truck enhancing your service efficiency, and a comparative view of 16-wheeler trucks versus 16-foot trucks to clarify their distinct roles in logistics and transportation. Each chapter will unveil how these trucks can be a game-changer for your business operations.

在冷链前线的紧凑巨兽:16英尺冷藏/冷冻厢式货车的设计与性能全景

清晨的车场还带着夜色的余温,一辆16英尺长的冷藏厢式货车静静停靠在灯光下。它并非市场上体量最大的运输工具,却以紧凑的箱腔体积、稳定的温度控制和耐用的机身在冷链运输中扮演着不可替代的角色。它的设计不是为了追求耀眼的外观,而是为了在有限的空间内实现极致的热管理、载荷效率和人机协同。这种平衡的艺术,来自对结构的严谨理解、材料的科学选择,以及制冷系统在不同环境下的精准调控。它让新鲜蔬果、乳品、海鲜甚至疫苗等需要温控的货物在运输途中保持品质,避免质量波动带来的成本与浪费。\n\n从结构层面看,16英尺冷藏厢式货车通常采用全封闭的箱体设计,箱体本身的刚度直接决定了在公路起伏、转弯与制动时货物的稳定性。为了实现高强度与轻量化的统一,制造商在箱体材料上偏向复合材料与高强度钢的组合,辅以黏接或铆接工艺来增强接缝的密封性和整体承载力。与之相配的底盘也经过专门的冷藏车标定,确保发动机在低转速时的运转稳定性,避免在满载时出现能耗上升或动力不足的情况。箱体的宽度通常设计在接近2450毫米的区间,以便在不牺牲跨距的前提下,最大化货物的堆放密度与装卸效率。这一数值不仅关系到日常运营的高效性,也对 pallet 的标准化布局与运输成本产生直接影响。\n\n在隔热与保温方面,16英尺冷藏车的核心是“断热—断桥”结构的应用。内外蒙皮往往选用导热系数极低的材料组合,通过在箱体墙体中填充高密度聚氨酯泡沫来实现厚实而连续的保温层。独立的制冷机组则负责把箱体维持在设定温度,通常有能力将车厢温度降至-15℃到-18℃的区间,以覆盖生鲜食品、肉类、乳制品、海鲜等对低温要求严格的货物。墙壁多采用1.5毫米厚的玻璃钢蒙皮,而门框和门饰件则偏向不锈钢材料,既保证耐腐蚀性,又利于清洁与卫生。在这样的结构支撑下,厢体与外部环境之间的热桥被有效地抑制,热量的传导被显著降低,货物温度的波动被控制在一个可接受的范围内。\n\n实用性与承载力则是设计中的另一项关键考量。车厢的内部布局通常考虑到高效的装卸与货物保护之间的折中。考虑到许多货物是分层、分区运输,箱体会留出灵活的内部空间,以适配不同类型的货物。双开门设计在许多车型中成为常态,便于快速装载、快速出库,尤其在高峰时段,装卸效率的提升直接转化为物流效率的提升。底板的加厚与横梁的密集分布,结合高强度的铆接式车架,确保长时间运行下的变形控制,从而减少货物在路途中的撞击与震动带来的损坏风险。对于食品级运输而言,材料的耐腐蚀性与卫生性亦不可妥协,FRP墙面、304不锈钢门框和接触面材料的选择,都是为了在高湿、高盐环境下维持清洁与安全。\n\n温控系统的设计与运行策略是整车性能的心脏。独立制冷机组的选择、布置与维护,决定了温控的响应速度与能耗水平。冷却循环系统需要在不同工况下快速响应,包括起步阶段的快速降温、满载时的温度维持,以及在极端天气条件下的温度波动抑制。箱体内的通风与蒸发器布置要确保冷气均匀分布,避免局部热点区域。为确保灾害性温度波动的风险降到最低,许多系统还引入了温度传感器网络、数据记录与远程监控,促使运营者可以在运输途中实时了解货物状态,并在必要时采取纠偏措施。\n\n从卫生与安全角度看,食品级材料的使用并非仅仅出于合规,更是对消费者健康与企业信誉的承诺。内壁通常选用易清洗、无缝或低缝隙的材料,尽可能减少藏污纳垢的缝隙;门沿与接口处的密封条要具备良好的耐化学性与耐水性,确保长期使用中的密封性不被破坏。所有与食品接触的部位都应具备可追溯性与清洁记录的能力,以满足日常清洁、消毒和安全合规的要求。断桥式保温结构不仅有助于热损失的减少,也有助于降低箱体内壁在温度变化下的热胀冷缩应力,减少长期使用中的变形可能性。\n\n在实际运行中,运输企业往往需要在节省燃油成本与车内温控稳定之间找到平衡点。车辆的能耗与温控系统的协同效率在很大程度上决定了单位货物的运营成本。通过优化箱体材料、保温厚度与制冷机型的匹配,可以在不牺牲货物品质的前提下实现更低的能耗。这也是现代冷链设备不断追求的目标:在不利天气、海拔差异与道路条件变化较大的场景下,维持货物温度的一致性,同时确保驾驶员具备可控、可预测的行驶体验。\n\n这种设计思路也影响着箱体的灵活性与可持续性。随着冷链场景的日益多样化,单一用途的货车逐渐转向模块化、可定制的内部配置。模块化并不意味着牺牲保温与结构性,恰恰相反,它让运营者能够根据不同货物类型进行快速再配置:提高高价值食品的冷链保护、为药物运输提供额外的温控参数、或为小型餐饮车队提供可变的内饰与设备布局。通过优化内部设备的位置、扩展接口与电力配套,16英尺冷藏车在灵活性与可靠性之间找到了一个平衡点。\n\n如果将技术脉络放在更宏观的视角,16英尺冷藏/冷冻厢式货车的设计正体现了冷链运输的核心原则:以最小的容积实现最大的温控稳定,以最少的能耗实现更广泛的应用。其紧凑的箱体、精细的保温、可靠的制冷系统以及卫生安全的材料选择共同支撑着食品安全、药品监管和紧急物资保障等多领域的需求。这些车辆在区域性配送、跨城运送乃至应急调度中都显示出独特的价值——它们不是单纯的运输工具,而是稳定供应链的一部分。\n\n对于有意在这条细分领域深耕的人来说,了解尺寸、配置与运行维护之间的关系尤为重要。若需要对不同车型的尺寸、布局与性能参数进行对比,可以参考以下资源中的实践要点与图解:16-foot-box-truck-penske。该资料以直观的方式呈现箱体宽度、门布置、内部高度及载荷容量的关系,有助于运营者在选型阶段就把“温控需求”与“操作便利性”放在同等重要的位置。\n\n在未来的发展中,16英尺冷藏/冷冻厢式货车还将进一步结合信息化、传感化和智能监控手段,提升对温度、湿度、震动等多维度环境变量的掌控能力。通过数字化的温控数据、预警系统和远程诊断,运营者可以更主动地管理冷链风险,减少因温度异常带来的损耗与赔偿。与此同时,材料科学的进步也将推动更高效的保温解决方案问世,使同样的箱体尺寸在更广的温区范围内保持平衡,进一步提升运输的灵活性与经济性。\n\n综上所述,16英尺冷藏/冷冻厢式货车的设计与性能不是单一因素的产物,而是一门融合结构工程、材料科学、热工学与运营管理的综合学科。在有限的体积里,如何最大限度地抑制热损失、维持货物品质、实现高效装卸和低成本运行,是设计师、制造商与运营者共同追求的目标。这种紧凑而强韧的系统,正是现代冷链物流在区域内稳定配送的关键环节,也是推动食品安全、医疗物资保障与餐饮服务多样化的重要基础。\n\n外部参考与进一步阅读:如需了解更具体的保温材料选择与结构细节,可以参阅权威技术资料以获得对比与解析。外部权威参考链接: https://www.foton.com.cn/product/detail/297

Sixteen Feet of Sizzle: The 16-Foot Mobile Deep-Fryer Truck and the Transformation of Street Food Mobility

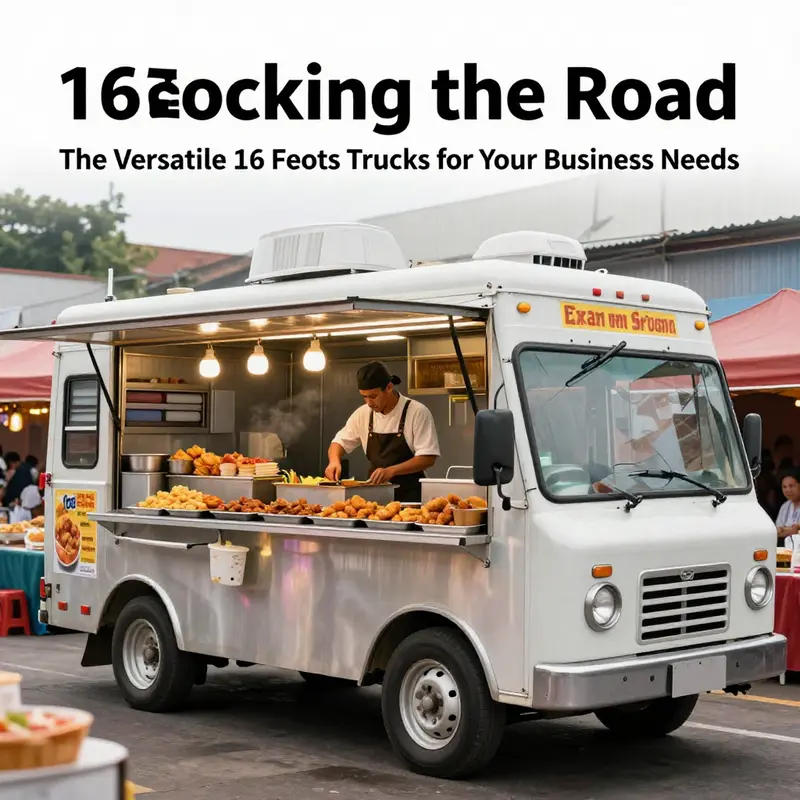

In many cities where the rhythm of life rolls from morning markets to midnight streets, a compact, purpose-built cooking platform has emerged as a powerful catalyst for small business and culinary experimentation. The 16-foot mobile deep-fryer truck sits at a compelling intersection: it is large enough to house a professional frying workflow, yet small enough to navigate crowded neighborhoods, festival grounds, and pop-up corridors that larger food trucks shy away from. What makes this vehicle more than a novelty is its ability to blend a scaled kitchen with urban agility, turning a modest footprint into a mobile restaurant that can pivot from breakfast sandwiches to late-night fried specialties with minimal downtime. The topic of this chapter, rooted in the broader exploration of “truck 16 feet,” invites us to see how this particular 16-foot variant reframes what is possible on wheels. It is not merely a transport shell with kitchen equipment; it is a carefully designed operating platform that fuses safety, efficiency, and branding into a single rolling asset.

Perhaps the most striking feature of the 16-foot deep-fryer truck is the way its core cooking technology is integrated with an intentionally small, highly functional footprint. The heart of this machine is a professional-grade frying station, usually comprising one or more large oil vats that range in capacity, often in the 30 to 50 liter category. The design recognizes that frying is both a high-volume and a high-output operation. When the sun climbs high in the sky and the lunch rush arrives, the ability to deliver hot, crispy products quickly becomes a defining competitive edge. Yet speed alone is not enough. The equipment is mounted within a stainless steel chassis that supports a clean, shipshape kitchen workspace. This is not a mere assembly of parts; it is a clamped-together workflow where raw ingredients, oil, heat, and service communications all align to minimize movement and maximize throughput. The result is a kitchen on wheels that feels both industrial-grade and surprisingly efficient in flow—an essential requirement for operators who must serve dozens of customers every hour while maintaining consistent product quality.

Inside this 16-foot frame, the interior layout often adopts a modular approach. Not every operator will want the same configuration, so the space is designed to be reconfigurable without sacrificing speed or safety. A typical arrangement places the fryers at the heart of the operation, flanked by stainless steel prep surfaces, a compact cold storage unit or an under-counter refrigerator, a sink with adequate filtration, and a venting solution that keeps the workspace breathable and compliant. The design goes beyond a simple kitchen layout; it cultivates a seamless service experience. An open-service window or porch is common, with a wide glass panel or pass-through that enables quick handoffs between staff and customers. This open-interface design is not just aesthetic; it encourages interaction, risers the tempo of service, and helps the operator gather feedback in real time. For the customer, the experience is transparent and inviting: you can see the fryers at work, watch the golden crust form, and feel the heat of the station while you decide what to order. The consistency of the fry, the clarity of the workstation, and the familiarity of the aroma all contribute to a sense of reliability that is often missing in street food offerings.

A crucial design feature that deserves emphasis is the oil management approach. Oil is not simply contained; it is controlled and repurposed in a way that reduces smoke and odor while promoting cleaner operation. Some configurations employ vertical burner structures and a water trough system that traps oil and directs it into a water-filled catch, which significantly suppresses smoke generation. This emphasis on smoke reduction is more than comfort; it is a strategic choice for compliance and city-permit viability. Traditional outdoor frying can trigger complaints about air quality and nuisance smoke in dense urban areas. By minimizing visible fumes and controlling the dispersion of grease runoff, the 16-foot deep-fryer truck positions itself as a more city-friendly option. Operators can operate longer hours in venues with strict smoke controls, and they can maintain a healthier, more comfortable workspace for staff who spend long shifts near hot oil. In addition to these smoke-minimization strategies, the kitchen components are often selected for corrosion resistance and easy cleaning. High-grade stainless steel surfaces resist the wear of frequent cleaning, oil splatter, and frequent contact with moisture. The entire interior is designed with hygienic workflows in mind: bacteria are kept at bay by rounded corners, seamless junctions, and a drainage system that runs efficiently to a proper waste line, a configuration that supports hygienic food preparation.

Power, energy, and reliability are equally important. The 16-foot trailer or truck typically supports multiple electrical configurations to accommodate different festival spaces, street corners, and event venues. The electrical architecture commonly offers 110V, 220V, and sometimes higher voltages, with some models featuring dual-circuit arrangements and, in more autonomous setups, battery backups that can sustain essential functions for several hours when the main power source is unavailable. This flexibility proves crucial for pop-up events, where access to grid power may be variable or where customers expect continuous service through peak times. In addition to electricity, fuel delivery and energy efficiency are considerations in the overall design. Some units are configured for propane or other gas inputs for the fryers, while others are wired to operate on electric fryers. The decision often hinges on local regulations, the type of neighborhood markets the operator intends to serve, and the cost structure of oil and consumables over the life of the business. The deployment of ozone or recirculating air systems for ventilation further enhances the working environment, ensuring compliance with safety standards while maintaining a comfortable temperature within the operator’s cabin.

Durability is another key pillar of the 16-foot deep-fryer truck. The chassis, body, and fittings are typically built from high-strength stainless steel or aluminum alloys known for corrosion resistance, rust prevention, and long-lifetime performance in outdoor settings. The mobility of these rigs is not merely about moving from one location to another; it is about surviving the daily trials of street life. Road vibrations, sudden weather changes, and the friction of frequent set-up and break-down all demand resilient construction. Wheels, axles, and hitch systems are chosen to withstand repeated use and long hours of operation while maintaining a safe and stable footprint in crowded venues. The overall payload capacity is often substantial for a vehicle in this class, commonly in the range of around 1800 to 2000 kilograms, which translates into the ability to carry heavy frying equipment, cold storage, and a supply of ingredients without compromising stability. This balance of power and portability makes the 16-foot deep-fryer truck an attractive option for small business owners who want a strong storefront presence on wheels without committing to a larger, more expensive rig.

From a branding perspective, the external presentation of these units matters as much as the internal efficiency. Operators frequently customize exterior finishes with branding elements that capture attention in busy environments. Exterior paint, illuminated signage, and magnetic panels enable rapid brand deployment at a street fair or in a shopping district. The goal is to blend form and function: a visually appealing vehicle that also functions as a fully capable kitchen. Some operators push the envelope with modern design languages that evoke hospitality or street-art aesthetics, leveraging the vehicle as a mobile billboard that travels from one hot location to the next. The combination of practical kitchen design and compelling branding is what makes these units not just tools, but portable business platforms with a distinct personality.

The market context surrounding the 16-foot mobile deep-fryer truck reveals a dynamic ecosystem of opportunities and constraints. In many urban centers, street-food economies are thriving as people seek quick, flavorful meals that are both affordable and novel. The 16-foot footprint hits a sweet spot: enough cooking capacity to handle busy periods, yet compact enough to access spaces where larger trucks cannot easily operate. The smaller size reduces entry barriers for new entrepreneurs, allowing a lower upfront investment relative to larger mobile kitchens. Reported price ranges for new configurations in certain markets sit in a broad band—illustrative of the growing market for adaptable, modular food trucks—ranging roughly from several thousand dollars to around ten thousand, depending on equipment levels, insulation, electrical systems, and branding features. This price landscape reflects a balance between durability, capability, and the desire for vendors to customize to local tastes and event calendars. For readers seeking a deeper dive into the broader landscape of 16-foot configurations and their governance, a general guide to 16-foot trucks can be found here: 16-foot truck.

The applications for a 16-foot deep-fryer truck extend well beyond a single cuisine. Operators often design multi-venue itineraries that exploit the vehicle’s versatility. A typical schedule could begin with a breakfast service focused on items like pastry-based offerings or specialty breakfast sandwiches, transition into lunch with fried classics such as chicken tenders or fish bites, and culminate in dinner or late-night snacks with more indulgent fried options and accompanying beverages. The ability to reconfigure the interior to accommodate a variety of equipment—fries and fried proteins, warmers, cold-case storage for toppings, a beverage station, and even compact driplines for coffee or tea—transforms the truck into a platform for “one vehicle, multi-identity” operation. In practice, this means one business can pivot its menu with minimal downtime, maintaining customer interest and sustaining revenue across different times and events. When deployed at markets, festivals, university campuses, or tourist corridors, the unit’s mobility enables a rapid test of new offerings and branding narratives. The operational data from pilots and early-stage operators consistently show that the ability to relocate quickly, while maintaining a consistent quality of product, enhances both customer loyalty and the potential for recurring revenue.

Operationally, the 16-foot deep-fryer truck can also serve as a case study in lean improvisation. Because street and festival environments often demand rapid setup and takedown, the equipment is designed to minimize the steps required to prepare for service. The operator can pre-stage ingredients, oil, and prep items in a way that reduces congestion at the service window. The fry operation, while compact, benefits from a well-considered workflow that includes guarded oil replenishment points, an efficient filtration or oil recycling process, and an organized separation of hot and cold zones to minimize cross-contamination. Staff training is an essential complement to the mechanical design; operators must be adept at oil management, fryer calibration, temperature control, and rapid cleaning protocols to comply with health regulations and to extend the life of the equipment. The overall maintenance burden in a 16-foot unit emphasizes quick-clean routines after each service and a predictable replacement schedule for consumables and safety components. In the longer arc, these maintenance practices become part of the brand promise: that customers will receive consistently fresh products prepared in a clean, safe, and approachable environment. The integration of technology into this operating model—such as apps for remote control of lighting or audio systems in some configurations—further enhances the customer experience and helps operators manage peak times with greater confidence.

In terms of broader impact, the emergence of 16-foot mobile deep-fryer trucks contributes to a reimagined urban food economy. They offer a lower-cost entry point for aspiring food entrepreneurs who want to prove a concept, build a local following, and learn the rhythms of outdoor cuisine without the heavy overhead of a fixed storefront. The mobility aspect aligns with the contemporary consumer’s appetite for flexible, “on-demand” dining experiences, where the vehicle itself becomes a part of the brand story. Social media amplifies this effect; visually striking vehicles and the theater of frying can draw crowds, encourage foot traffic, and become recurring content for online communities. The shape, color, and light patterns of these trucks—often highlighted with LED accents or signage—make them highly sharable assets for aspiring restaurateurs and established operators alike. The result is a new form of culinary entrepreneurship that looks outward, inviting pedestrians to become customers and then fans, all in the span of a few square meters of street frontage.

If we zoom out to view the landscape more broadly, a 16-foot deep-fryer truck is more than a specialized cooking rig. It is part of a continuum of 16-foot and near-16-foot food and service vehicles that can bridge the gap between stationary retail outlets and fully mobile, flexible food experiences. In practice, the 16-foot format can be seen as a bridge between the compact, street-level vending concepts and larger, more complex concession operations. This bridging function is what makes the 16-foot category particularly relevant to discussions about modern mobility, entrepreneurship, and urban food culture. It invites readers to think about not only what the vehicle does, but how its form, capabilities, and cost structure influence the decisions of operators who are rethinking where and how to feed communities. The potential for growth lies not only in the number of menus that can be supported, but also in the ability to create partnerships with event organizers, campuses, and neighborhoods that value quick-service options that are both tasty and responsive to local tastes. The dynamic nature of the urban food scene means that the 16-foot mobile deep-fryer truck is positioned to adapt as demographics shift, as event calendars change, and as consumer expectations evolve toward faster, more personalized service.

In closing, the 16-foot mobile deep-fryer truck embodies a philosophy of compact capability. It shows how a well-conceived kitchen on wheels can deliver professional-grade cooking, sustainable operation, and compelling brand experiences within a footprint that remains accessible to many aspiring operators. It is a reminder that innovation in mobility often begins with a precise question: how can we bring the energy and flavor of a full kitchen into a vehicle that easily navigates the city’s tight corners and crowded venues? The answer, as demonstrated by this 16-foot class, is that the right combination of equipment, layout, and branding can transform a modest truck into a mobile culinary platform capable of sustaining both craft and commerce across diverse urban contexts. For readers who want to continue exploring the broader ecosystem of 16-foot vehicles and their uses, a general guide to 16-foot trucks is available here: 16-foot truck.

External reading: https://www.made-in-china.com/products-search/hot-products/16FTfoodtruckusacustomizedfoodtrailerwithfullkitchenequipment.html

Length and Wheels on the Move: Decoding 16-Foot Trucks versus 16-Wheel Giants

Apportions of road and purpose converge in the quiet arithmetic of the fleet. When you hear the phrase truck 16 feet, the mind often imagines a compact, city-friendly workhorse designed to slip through tight streets with ease. But when the term shifts to 16 wheels, the image pivots to something built for weight and distance—a heavy-haul machine engineered to shoulder enormous loads across the highway network. The juxtaposition between a 16-foot truck and a 16-wheel truck is not merely a matter of size or number of tires; it is a study in how form meets function, how urban practicality meets long-haul necessity, and how a single dimension—either the length of the body or the count of wheels—redefines a vehicle’s design, capabilities, and intended use. In this chapter, we thread together the practical implications of these differences, showing how a small difference in what a truck carries, and how far, translates into decision-making for fleets, operators, and businesses that depend on reliable transport every day. The conversation above is not abstract rhetoric; it is the language of yards, docks, dispatch centers, and street-front storefronts that rely on predictable, safe, and cost-efficient movement of goods and services across time and terrain. To set a reliable stage, it is helpful to anchor the discussion in two primary categories that often appear in the real world under the umbrella of “16 feet”: temperature-controlled goods and specialized mobile food service. Each of these exemplifies how a 16-foot body can be configured to sustain a distinct value proposition, while the broader category of 16-wheel trucks embodies a very different set of economic and logistical realities. The heart of the matter lies in how length and wheels translate into payload capacity, maneuverability, regulatory exposure, and long-term operational costs—factors that determine not only what gets moved, but how and where it travels. Consider first the 16-foot refrigerated or temperature-controlled van. The appeal of a refrigerated 16-foot box lies in the promise of stable, controllable temperatures that preserve perishable items, medicines, or any cargo that demands a consistent climate. In practice, these vehicles integrate a dedicated refrigeration system that maintains defined setpoints, often with modern sensors and fail-safes to guard against excursions that could compromise product quality. The alignment of a 16-foot footprint with refrigerated technology is no accident; the length is long enough to accommodate a reliable evaporator and condenser layout, yet compact enough to navigate urban corridors and loading docks with a degree of ease that larger or longer trucks cannot match. This balance matters when speed-to-delivery is critical, such as in fresh-produce distribution, pharmaceutical transport, or niche medical supply chains where product integrity hinges on both temp control and timely arrival. Emission standards and regulatory compliance further shape how a 16-foot reefer is imagined and deployed. In a modern fleet, environmental considerations are not peripheral; they drive choices about engine technology, refrigerant management, and overall vehicle lifecycle planning. A 16-foot reefer that adheres to current emission norms reduces the likelihood of costly retrofits and the risk of noncompliance-caused downtime. The design ethos extends beyond the cab and chassis to include the box itself, where insulation quality, door seals, and cargo access influence energy efficiency and ease of loading. In many setups, the interior configuration is optimized for the type of cargo, with modular shelving, temperature zones, and smart monitoring that keeps a constant eye on temperature, humidity, and door activity. The result is a mobile unit that preserves product integrity from dock to door, with predictable energy usage and a service profile that aligns with tight distribution windows. The second 16-foot configuration under the same umbrella—an explicit counterpoint to temperature-sensitive goods—appeals to a different class of operators: those who value the mobility and tacit reliability of a portable kitchen or food service unit. Across many markets, a 16-foot mobile deep fryer trailer embodies the art of compact culinary production in a rolling, outdoor-ready package. This vehicle is purpose-built for high-output cooking in a compact footprint, with a focus on durability, customer interaction, and rapid service in environments ranging from festival grounds to busy street corners. The core strengths here are different from refrigerated logistics but no less essential: durability in outdoor conditions through corrosion-resistant construction, a design that invites customer engagement through open access and expansive glass views, and a layout that translates a tight linear space into efficient workflow. The modular approach to this class of vehicle is particularly notable. Operators can reconfigure internal equipment to support a spectrum of offerings—from high-end, curated menus to popular street fare—without sacrificing compliance or safety. A design anchored in food-grade materials and validated by CE and ISO standards reduces regulatory friction and increases confidence among operators who must meet strict health and safety requirements. The third facet of the “16 feet” conversation, as some readers may encounter it in broader discussions, is the term 16-wheel truck. The terminology is crucial, but its meaning is frequently misunderstood when juxtaposed with a 16-foot body. A 16-wheel truck is defined by the wheel count rather than the cargo length; it is a heavy-duty vehicle designed for weight-bearing and stability across demanding routes. This category often involves a tractor-trailer arrangement with multiple axles distributed to manage enormous loads, from construction materials to oversized machinery. The practical implications are clear: more axles distribute weight more evenly, yielding improved traction, braking, and roadholding in challenging conditions. The trade-off, however, is a larger footprint, higher maintenance demands, and regulatory complexity that accompanies heavy, multi-axle configurations. It is not uncommon for a fleet to operate both types of equipment in a single day’s work—one leg of the journey might require the precise, climate-controlled handling of a refrigerated 16-foot box, while another leg calls for a 16-wheel configuration capable of moving a wind turbine blade, a transformer, or other heavy payloads over long distances. Reading these pieces together reveals a robust schema: when length dictates the kind of cargo and the urgency of delivery, fleets optimize the route and the vehicle to match the mission. The 16-foot class, whether refrigerated or kitchen-ready, emphasizes manageable scale, nimble routing, and the ability to service urban areas with minimal disruption. The 16-wheel class emphasizes payload heft, route assurances on long corridors, and the capacity to carry the kind of heavy, bulky goods that demand distribution over many miles and a strong margin for safety and compliance. The difference between these two branches, then, is not merely a question of which side of the road one sits on; it is a reflection of how a business defines its value proposition. If speed and product integrity in a time-sensitive, temperature-controlled window are the baseline, a 16-foot unit becomes a core operational asset. If the aim is to mobilize heavy, industrial-scale payloads across interstate corridors, the 16-wheel configuration embodies the logistical backbone of the supply chain for bulky, high-weight loads. Reading the details of the two 16-foot variants—refrigerated and culinary—through this lens highlights a common thread: the length of the vehicle acts as a constrained, predictable template for equipment placement, food safety practices, and energy management. Yet the consequences of that template are profound. The shorter body supports easier maneuvering, quicker lane changes, simpler docking at urban facilities, and more forgiving parking challenges. The longer, multi-axle design supports greater gross vehicle weight, enhanced stability on unpaved or uneven surfaces, and the potential to haul items that would overwhelm a smaller platform. These factors translate into real-world decision making. For a distributor serving metropolitan neighborhoods, the 16-foot refrigerated option unlocks a reliable cold chain with limited space for inventory but substantial control over temperature swings and spoilage risk. A mobile food operation, meanwhile, might view the 16-foot deep fryer trailer as a strategic investment that creates a portable, compliant kitchen able to reach diverse crowds while optimizing throughput and drive-through-style service. In both cases, the critical questions revolve around how to balance space, weight, and operational tempo. What is the cost of underutilized capacity? How often will the vehicle sit idle, waiting for a cargo that fits not only in volume but in weight and temperature profile? What maintenance cycles are warranted to preserve refrigeration efficiency or cooking equipment reliability across shifting seasonal demand? These questions underscore the pragmatic nature of choosing between 16-foot and 16-wheel solutions. They are not theoretical debates but concrete planning decisions with implications for fuel consumption, driver training, insurance, and uptime. The literature and field experience converge on a consistent theme: the most effective fleet mix aligns vehicle capabilities with the cadence of business demand. When the cadence favors frequent, small-volume deliveries within a city, the shorter 16-foot footprint with its compact radius and flexible loading points can deliver cost and time advantages. When demand involves occasional heavy-lift tasks, long-haul routes, or the need to move unusually large cargo, the 16-wheel configuration becomes indispensable, even when it requires more complex routing and more stringent regulatory oversight. The practical takeaway for operators and planners is to avoid the trap of assuming one vehicle type is universally superior. Instead, the wiser path is to design a mixed fleet that matches the nuances of service lines, customer expectations, and the geography of the service area. A well-considered fleet composition anticipates peak periods, seasonal shifts, and the inevitable variability of real-world operations. It also recognizes that a 16-foot unit is not merely a smaller version of a larger truck, just as the 16-wheel behemoth is not a cousin to the conventional box truck. Each configuration brings a unique blend of capabilities, constraints, and opportunities, and each serves a distinct role in the broader logistics ecosystem. The narrative here is not only about physical measurements but also about the operational culture that grows around those measurements. The 16-foot model emphasizes disciplined inventory planning, precise loading, and exact temperature management. Its success depends on speed, consistency, and the confidence that goods arrive in the promised condition. The 16-wheel model depends on scaling, route discipline, and the confidence that the fleet can shoulder heavy payloads under demanding conditions. The two paths converge in one essential truth: the road is a resource that must be allocated with foresight, not just speed. In practice, managers often rely on a simple but powerful framework to guide choices. They map the cargo profile—weight, volume, temperature sensitivity, and fragility—against the controllable variables of the vehicle: length, axle count, and the installed equipment. From there, they consider the route topology, the typical distance to the first and last mile of delivery, the parking and loading infrastructure available at facilities, and the regulatory environment governing vehicle operation. In regions where cold chain integrity is paramount, the 16-foot reefer box frequently emerges as the most reliable workhorse for daily duties. In markets that prize on-site production capacity and street presence, the mobile kitchen solution within the 16-foot class reveals a different, equally compelling value. And in sectors where heavy, bulky goods define the core business, the 16-wheel platform is the logical backbone of the fleet. Across all these considerations, one constant remains: the importance of clear, data-driven decision-making. Fleet managers who invest in accurate payload estimation, equipment reliability, and regulatory literacy are rewarded with higher uptime, lower incident rates, and more predictable operating costs. The dynamic balance between 16-foot and 16-wheel configurations is not a one-time choice but an ongoing recalibration as markets evolve, technology advances, and customer expectations shift. The best outcomes come from a holistic view that integrates vehicle design with service design. It means aligning the physical capabilities of the truck with the operational discipline of loading, routing, and maintenance. It means understanding when a cold chain must be protected against ambient shocks, when a kitchen must scale up to meet peak demand, and when a heavy-lift operation requires the steadiness of a multi-axle platform. It also means recognizing when a single vehicle can fulfill multiple roles, sometimes through modular equipment and flexible configurations that allow rapid retooling without sacrificing safety or compliance. For readers who seek to deepen their understanding, a practical touchstone is to examine how different vehicle classes are described in industry literature and regulatory guidance. As the discussion above demonstrates, the metrics that matter—payload capacity, stability, maneuverability, and compliance readiness—are not abstract numbers but the levers that determine whether a truck can perform reliably from dock to door and back again. In the end, the question is less about which is better and more about which is fit for purpose. A business serving a dense urban core with frequent small shipments will likely favor the nimble 16-foot class with its advantageous turning radius and loading flexibility. A business that moves large, unwieldy items across lengthy stretches of highway will lean into the stability and high payload potential of a 16-wheel platform. The best fleets embrace both worlds, optimizing allocation by trip profile, cargo type, and time sensitivity. In that sense, the distinction between 16-foot and 16-wheel vehicles is a microcosm of broader logistics strategy: choose the tool whose strengths align with the task at hand, and design processes that exploit those strengths without inviting avoidable risk. For readers who want a concise gateway into one of these paths, a practical, quick-reference overview of 16-foot configurations can be found in a broader discussion on vehicle types and dimensions. This resource offers a compact snapshot of how 16-foot bodies are sized, configured, and used, including the urban-friendly advantages of such platforms. You can explore a focused overview at the dedicated chapter on 16-foot transport, which clarifies how these vehicles are structured and what missions they are best suited to support. 16-foot-truck Beyond the numbers, the narrative remains grounded in a simple, enduring truth: transport is most effective when it is designed to perform the task at hand with reliability, safety, and cost discipline. Whether the mission demands the precise temperature control of a refrigerated 16-foot van or the heavy-lift steadiness of a 16-wheel configuration, success hinges on thoughtful alignment of vehicle capability with the real-world rhythm of supply and demand. The road will always test equipment, and the fleets that endure are those that plan for both the common and the exceptional. External considerations, such as evolving emissions standards, safety regulations, and industry best practices, only reinforce the need for a deliberate approach to vehicle selection. As markets shift and new materials, fuels, and propulsion options begin to redefine what is possible, the choice between a 16-foot box and a 16-wheel rig remains one of the most fundamental in transportation planning. It is a choice that shapes not only how goods move, but how businesses grow, how customer expectations are met, and how the everyday flow of commerce sustains communities. For practitioners, the next step is to translate these insights into concrete fleet decisions—documenting cargo profiles, testing configurations through pilot routes, and calibrating maintenance and training to the realities of day-to-day operations. The goal is a fleet that is not merely large or fast, but fit for purpose, adaptable, and resilient under the pressure of real-world demand. External resource: Truck Size and Weight Limits by the Federal Highway Administration provides authoritative context on how the wheel count, axle arrangements, and vehicle dimensions relate to legal limits and practical performance across different jurisdictions. https://www.fhwa.dot.gov/publications/fhwasa19027/

Final thoughts

Selecting the right truck is essential for enhancing your business operations. The diverse applications of 16-foot trucks, whether for refrigerated transport or as mobile kitchens, demonstrate their vital role in various industries. By understanding the distinctions between different types of trucks, including the powerful 16-wheelers, you can make informed decisions that optimize efficiency, reduce costs, and meet your unique business requirements. Equip your venture with the right vehicle and stay ahead in today’s ever-evolving market.