For business owners in need of efficient vehicle transportation, understanding the functionality and advantages of the Penske Car Dolly is crucial. This guide delves into the fundamental aspects of the Penske Car Dolly, exploring its role in vehicle transport, safety features, comparisons with alternative dollies, and customer experiences. Each chapter builds upon the last to furnish a thorough overview, empowering business owners to make informed decisions in their logistics operations.

Tow Dolly Essentials: Mastering the Basics of Car-Dolly Equipment

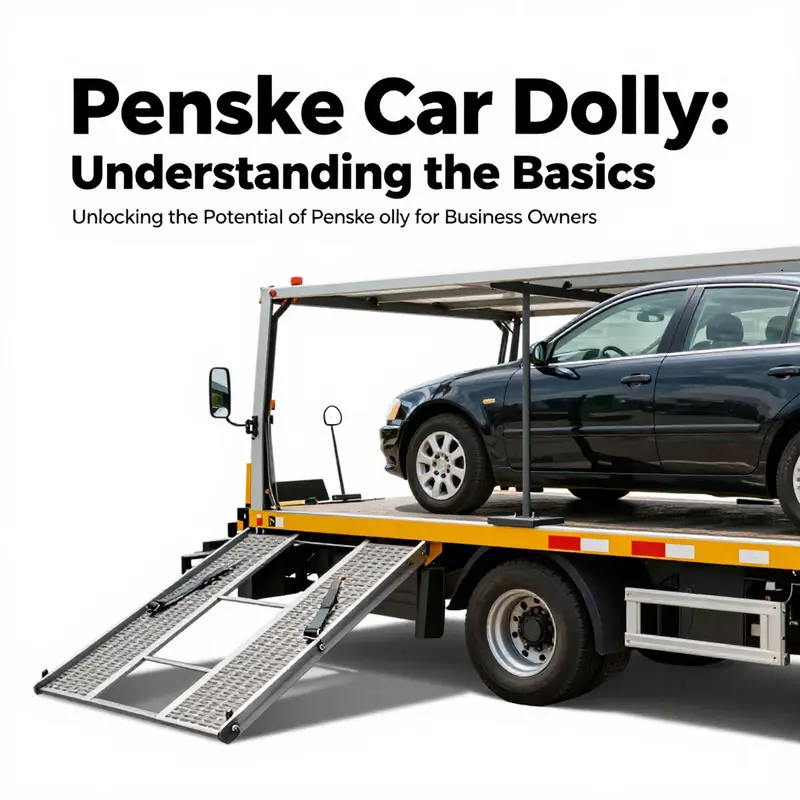

A car dolly offers a compact, economical way to move a vehicle without a full trailer. It sits between a simple hitch-haul and a full trailer, providing a stabilized platform for front- or rear-wheel loading while allowing the tow vehicle to maintain familiar handling. Proper loading, securing, and driving technique are essential for safety and control. The key ideas are weight distribution, reliable restraints, and ground handling so that nothing shifts during acceleration, braking, or cornering. Begin with a calm approach: ensure the dolly is on level ground, lights are working, and wheel chocks are in place. Move the vehicle slowly onto the platform so its wheels sit securely in the cradle. If the vehicle can run, put it in neutral and release the parking brake to let the weight settle onto the dolly. Secure the wheels with purpose-built straps, crossing them to prevent lateral movement and using additional anchors as needed to prevent fore–aft play. Check strap tension at rest, then recheck after a few miles and after long stops. Confirm the dolly’s connection to the tow vehicle: a properly sized hitch, appropriate tongue weight, and working lighting and braking circuits. Remember tongue weight: too little invites sway, too much can reduce steering stability. The dolly system relies on balanced mass, attention to the road, and disciplined driving. When selecting a dolly, prioritize a robust restraint system, a ramp that is easy to deploy, and a platform that accommodates the vehicle’s wheelbase without rubbing. Heavier or wider vehicles may require a larger platform or even a full trailer. Maintenance matters: inspect tires, straps, ramps, and attachment points before every move; replace worn parts; test lights and wiring. The ethical side of dolly use includes obeying weight limits, clearances, and local regulations; plan routes with adequate space for lane changes and avoid rough terrain that could jolt the load. Whether you own, rent, or borrow, understanding the basics—weight distribution, securement, and safe driving—will make car-dolly moves predictable and repeatable. For deeper technical insight, consult manufacturer guidelines and professional resources on wheel straps, anchor points, and safe ramp angles.

null

null

Safeguarding the Road: The Safety Architecture of Vehicle Transport Dollies in Fleet Operations

Vehicle transport dollies occupy a critical, often understated role in the machinery of fleet operations. They are not merely platforms for moving cars from point A to point B; they are engineered to preserve the integrity of the vehicle and the safety of everyone along the route. In fleets that move dozens or hundreds of cars, the safety architecture of these dollies—how they hold a vehicle steady, how they distribute weight, and how drivers are trained to use them—becomes a decisive factor in reducing risk, preventing damage, and protecting the people who rely on efficient, reliable transportation every day. The story of a car-dolly system begins with design choices that anticipate the forces a moving vehicle imposes: braking, acceleration, wind resistance, and the occasional unexpected jolt from a pothole or a sudden lane change. Against that backdrop, the most important features emerge not as single innovations but as an integrated suite of elements that work together to keep every mile secure. A car dolly is a transport tool that aligns robust construction with precise operational procedures, yielding a safer, more predictable towing experience for drivers, vehicles, and the roadway community alike.\n\nThe backbone of safe car-dolly operation rests on three interlocking pillars: secure tie-down systems, sturdy frame construction, and disciplined weight distribution. Each pillar supports the others, creating a stable, controlled environment in which a towed vehicle remains immobilized relative to the dolly and to the tow vehicle. A secure tie-down system is the first line of defense. High-strength straps, chains, or a combination of both are threaded through designated tie-down points on the vehicle and anchored to the dolly’s frame. The design emphasizes multi-point restraint, reducing the chance that any single connection could loosen or fail under load. The aim is simple: prevent even minor movement of the towed vehicle during braking, cornering, or rough road conditions. The dollies themselves are engineered with attachment points that resist wear and maintain tension over long distances. In practice, maintenance routines include regular inspection of these connections for fraying, corrosion, or any sign of fatigue, followed by re-tightening to the manufacturer’s specified torque or tension. Drivers learn that the tightness of the tie-downs is not a one-time task; it is a dynamic condition that deserves attention before departure and at periodic intervals along the journey. When done correctly, the vehicle becomes as immovable on the dolly as possible, which translates into less relative motion, less chance of damage, and a more predictable ride for the driver and surrounding traffic.\n\nThe second pillar, sturdy frame construction, matters because a dolly’s stability hinges on the integrity of its own bones. The frame is typically built from robust steel or other high-strength alloys, with cross-members and gussets that reinforce load paths and minimize flex under load. A well-constructed frame resists bending and torsional stress, maintaining alignment between the dolly wheels, platform, and hitch connection. This stability is not cosmetic; it directly affects how the towed vehicle behaves under braking and turning. A rigid frame reduces the likelihood of lateral shift that could otherwise loosen tie-downs or create a dangerous camber when the vehicle is in motion. Regular inspection for cracks, rust, or misalignment is essential, especially after long hauls or operations in harsh climates where corrosive elements can take a toll. A durable frame also underpins the longevity of the equipment, which matters to fleets that depend on consistent performance and lower maintenance costs. When drivers encounter a dolly with a solid frame, they experience a quiet confidence—the sense that the platform beneath the vehicle is designed to stay true to its geometry, even when the road throws a curveball.\n\nThe third pillar, proper weight distribution guidelines, ties into every decision a driver makes about loading, securing, and operating the dolly. Vehicle weight must be allocated in a way that preserves the dolly’s intended center of gravity and ensures that the combined mass of the vehicle, the dolly, and the hitch remains within safe limits. Manufacturers publish weight-distribution charts or guidelines that specify tongue weight, axle loading, and the maximum gross combination weight for the setup. Respecting these guidelines is not merely a matter of compliance; it is a driver’s practical toolkit for achieving predictable braking response, steering stability, and tire wear management. In the daily rhythm of fleet work, weight distribution is checked as part of a thorough loading routine. The operator verifies that the vehicle is centered on the dolly, the wheelbase alignment is correct, and the tongue weight is within the recommended range. This careful arrangement helps ensure that the towing vehicle maintains its braking efficacy, steering control, and overall stability, even when confronted with changing speeds or road grades. A disciplined approach to weight distribution also mitigates the risk of dynamic rollover under extreme maneuvers or sudden lane shifts. The result is a fleet that can deliver confidence to drivers and customers alike, because the mathematics of load and balance are aligned with the physics of motion.\n\nBeyond the core hardware, the soft infrastructure surrounding the dolly plays a decisive role in safety. Comprehensive training materials and safety guidelines are a constant companion to the hardware, guiding drivers through loading sequences, securement checks, and safe operation in varying conditions. This training is not a one-off indoctrination; it is an ongoing program that reinforces best practices, updates operators on any changes to equipment or procedures, and provides a framework for incident prevention. Drivers are taught to conduct a pre-trip inspection that covers the dolly’s tires, lights, hitch connection, and brake mechanism, alongside the vehicle’s own condition and the security of the tie-downs. They also learn to perform post-hook checks after a few miles and during stops to ensure that nothing has shifted under dynamic conditions. The value of such training becomes particularly clear on long hauls through diverse weather and traffic patterns, where the margin for error narrows and the consequences of a misstep can be significant. A culture of safety emerges when drivers understand both the mechanical limits of the dolly and the human responsibility of routine checks, enabling a smoother, more predictable operation for everyone on the road.\n\nAn additional, sometimes overlooked consideration relates to driving techniques during tow operations. Fleet professionals emphasize that features like cruise control, while useful for long hauls, should be used judiciously. In adverse weather, heavy traffic, or rapidly changing speed zones, relying on cruise control can blur reactive timing and slow the driver’s ability to respond to shifting road conditions. In the context of a vehicle-dolly combination, a quick reflex, deliberate throttle, and steady steering become part of the safety repertoire. The caution is not about discarding modern conveniences, but about understanding when a higher level of driver engagement is necessary to maintain control. This perspective integrates with the broader lesson of safety in transport: technology supports execution, but human judgment remains the essential governor of risk. When the driver remains attentive, adheres to loading and securing protocols, and respects the guidelines for weight distribution, the total system—from the vehicle on the dolly to the tow vehicle and the road ahead—stays aligned with safety aims rather than drifting toward avoidable danger.\n\nIn the grand scheme, the safety architecture of a car-dolly system is not a single feature but a disciplined ecosystem. It blends robust hardware with meticulous procedures, sustained training, and prudent driving practices. The outcome is a transportation capability that protects the vehicle being moved, preserves the condition of the equipment, and guards the people who share the road. For fleets, the payoff is clear: fewer incidents, lower maintenance costs, and higher reliability for customers who rely on timely, damage-free delivery. For drivers, the pathway to safety is paved with routine checks, precise loading, and the quiet confidence that comes from knowing the system built around them is resilient. In a world where every mile carries risk, a well-designed dolly and a well-trained crew form a hinge of safety that keeps moving forward with purpose.\n\nAs a practical takeaway, any operation contemplating more secure vehicle transport would do well to mirror the core principles described here. Emphasize secure, multi-point tie-downs; demand sturdy, well-maintained frames; insist on clear, documented weight-distribution guidelines; and sustain a culture of rigorous training and ongoing safety communication. Couple these with driver education on the prudent use of cruise control and the insistence on continuous attention during tow operations. The chapter of safety does not end with the purchase of a dolly; it continues with the daily rituals of loading, securing, and driving. In that ongoing practice lies the difference between a routine move and a costly, avoidable mishap. When fleets invest in the full safety ecosystem—from hardware to human factors—they translate engineering into real-world protection for people, vehicles, and the roads they share. External resource: https://www.nhtsa.gov

null

null

Tow-Behind Trust: Customer Voices on the Penske Car Dolly Rental Experience

Choosing a car dolly rental is about trusting a service and ensuring safe transport. For people moving homes or helping a friend, the experience hinges on two streams: equipment reliability and the support network behind it. The journey from reservation to return unfolds across touchpoints, from initial research to final return. The most meaningful feedback centers on how the equipment performs and how the company staff and systems respond when something unexpected occurs. This combination—reliable gear plus strong human assistance—shapes the overall impression more than any feature list. In the car dolly space, weight distribution, secure tie-downs, and alignment matter, raising the stakes for small moments to matter.

From the outset, the service model matters nearly as much as the equipment. A company with a broad rental network often highlights fleet maintenance, on-site expertise, and round-the-clock support as core values. Customers notice fleet condition: tires with adequate tread, brakes and lights working reliably, and frames that show ongoing inspection. When moving a vehicle, the last thing a customer wants is doubt about the hitch or the dolly’s ability to handle a grade. A thoughtful provider blends dependable gear with a safety-forward approach that translates into driver confidence.

Customer feedback in early 2026 points to the people behind the equipment: ease of interaction with staff, clear guidance during check-in, and practical problem-solving that reduces stress. The Penske Truck Rental network is frequently cited for professionalism, empathy, and technical know-how. Customers describe friendly, proactive teams that listen, diagnose, and offer options without pressuring a single path. This combination of skilled personnel and reliable gear fosters security on the road and trust in the rental partner.

The digital layer also matters. The Penske Truck Rental app is effective for locating and retrieving reservation details, speeding planning. Yet some steps can feel cumbersome, such as uploading documents or re-entering data if fields fail to populate. The system excels at retrieval but can slow self-service tasks that customers want to handle without support. Friction in reservation changes often lacks a direct phone contact. In those moments, a helpful staff member who can review documents or adjust bookings makes a big difference. The best experiences blend intuitive technology with capable human judgment.

The car dolly itself embodies safety and clarity: a capacity that matches vehicle weight, clear loading and securing procedures, and staff verification of alignment before departure. Customers value guidance on hitch setup, wheel chocks, and proper tie-downs, and they expect checks that prevent shifting cargo on the road. Prepared operators who can walk customers through steps reduce the risk of miscalculation.

As moves proceed, the human factor becomes most tangible: a well-trained crew translating specifications into on-site practice, ensuring the vehicle is strapped properly, and guiding smooth maneuvers to minimize sway. Customers appreciate transparent timelines and contingency options. Roadside assistance availability adds reassurance, offering a backstop if plans shift. This ecosystem of dependable gear plus responsive support translates into a less stressful, more predictable move.

Returning the dolly closes the loop: thorough post-move checks, clear communications about costs, and a straightforward process for future use. Positive wrap-up experiences reinforce that the rental was a partner in the move, not just a transaction. Across touchpoints, the core impression remains: a reliable tool supported by a capable, user-friendly ecosystem.

For readers seeking a practical overview, the Penske Tow Dolly guide provides structured steps for hitching, loading, securing, and safe transit, complementing experiential narratives with concrete safety considerations.

In sum, a car dolly rental anchored in well-maintained equipment, accessible staff, and robust support tends to build durable trust. Customers remember the people who help them problem-solve, the equipment’s behavior under load, and the harmony between digital and human elements. The most cited stories highlight staff who listen, explain options clearly, and follow through with disciplined operations, while recognizing room for digital improvements. The car dolly rental experience thus becomes a dependable chapter in a larger moving journey.

Final thoughts

Understanding the Penske Car Dolly is essential for business owners looking to streamline their vehicle transportation processes. From its basic functions to the intricate safety features, the benefits are clear. The Penske Car Dolly stands out in the market, not just for its efficiency but also for the positive testimonials from users who have integrated it into their logistics strategies. Prioritizing safe, reliable transportation means considering quality tools like the Penske Car Dolly for your business needs.