The landscape of logistics and transportation is continuously evolving, with various vehicles playing pivotal roles in operations. Among these, the term ’16 truck’ stands out, encompassing a range of models from dump trucks to advanced low-platform trailers. This article delves into the diverse applications of 16 trucks, providing business owners with a comprehensive understanding of their design, construction, and relevance in the industry. Each chapter elaborates on specific types of 16 trucks and their significance, laying the groundwork for strategic logistics decisions that can bolster business efficiency.

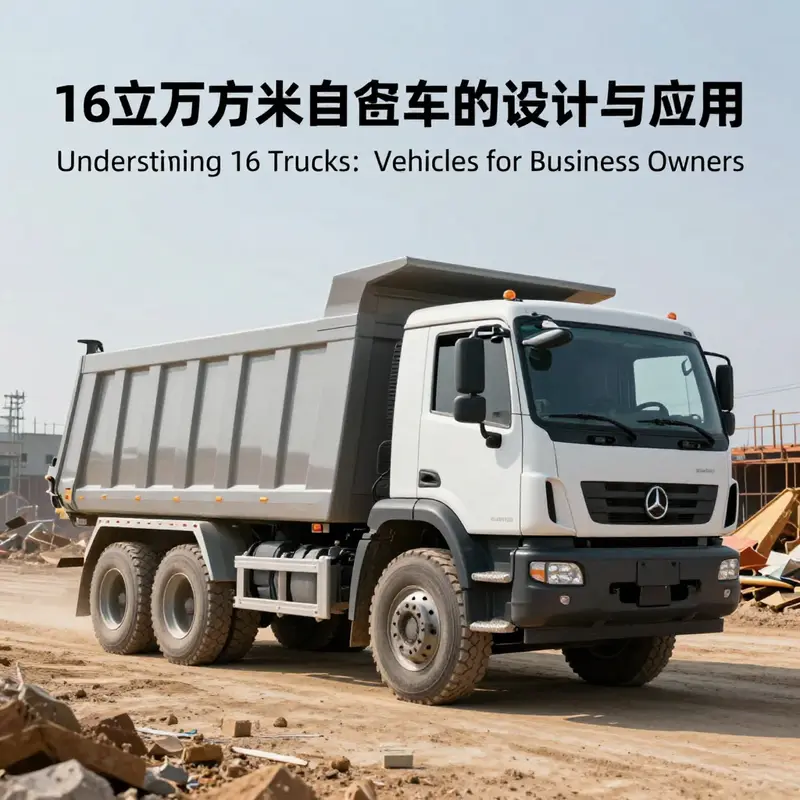

The 16-Cubic-Meter Dump Truck: Design Principles, Field Applications, and the Path to Cleaner Power

A 16-cubic-meter dump truck sits at a strategic intersection in the world of heavy transport. It is large enough to move substantial loads in a single haul, yet compact enough to navigate active construction yards, municipal sites, and quarry entrances without becoming a lumbering obstacle. The design challenge, therefore, is to harmonize a robust, long-lasting cargo box with a chassis and powertrain that can sustain high utilization, variable terrain, and demanding duty cycles. In practice, the 16 m3 figure translates into a payload often in the vicinity of twelve to sixteen metric tons, depending on the exact configuration and the material being carried. This payload sits atop a body engineered to resist wear from sand, gravel, ore, or sludge, while still enabling efficient unloading through a reliable tipping mechanism. The cargo bed itself is not simply a box; it is a carefully contoured chamber with liners, guard plates, and a robust tailgate, all designed to survive frequent cycles of loading, tilting, and return to service. A typical, durable bed is constructed of high-strength steel with wear-resistant linings in the impact zones and abrasion-prone corners. Such choices extend life in environments where the vehicle repeatedly confronts sharp rocks, gritty dust, or wet, clinging materials, and they help maintain the volume integrity that defines the “16 m3” benchmark over thousands of cycles rather than hundreds.

The frame and body geometry play a decisive role in how a 16 m3 dump truck handles its workload. The chassis must tolerate the weight of full loads and the dynamic forces produced when the bed rises to dump. This demands a reinforced ladder or truss-style frame, with cross-members positioned to distribute load and damp the impact of rough terrain. The way the body mounts to the frame, the position of the hoist cylinder, and the routing of hydraulic lines all influence stability during dumping and the smoothness of return to road alignment after a dump. As a result, manufacturers often offer multiple cab-to-axle lengths and bed depths, enabling operators to tailor the machine to a particular job, whether it be a tight urban site with limited turning radius or a sprawling mining operation where road grade and ground pressure dictate a more rugged setup.

Drivetrain configurations for a 16 m3 truck tend toward flexibility. A 4×2 arrangement can suffice for lighter, urban or lighter-material tasks, while a 4×4 or 6×4 setup broadens capability across loose, uneven, or high-payload applications. In mining and quarry environments, where ground adhesion and traction are critical, a multi-axle configuration with additional drive wheels and, in some cases, traction control, helps stabilize the vehicle under heavy loads and steep grades. Suspension systems are likewise chosen with terrain in mind; heavier steel springs or air-ride variants work to mitigate body roll when the bed is raised, helping the operator maintain control and minimize wear on the tires and structural components. While the precise balance of axles, wheelbase, and weight distribution varies, the overarching goal remains consistent: deliver predictable tipping performance, robust dump cycles, and a long service life under harsh operating conditions.

Powertrain choices for these machines are equally consequential. Traditional diesel engines continue to dominate in many markets, valued for their high torque output, reliability, and ease of refueling in remote sites. Yet the industry is steadily migrating toward options that reduce fuel consumption and emissions without compromising uptime. Hybrid approaches and pure-electric variants hold particular promise for applications with frequent loading and dumping cycles in the same site. An electric or hybrid powertrain can offer smoother torque delivery, reduced noise, and lower maintenance costs due to fewer moving parts in the drive system. However, the weight of batteries or hydrogen storage, cooling requirements, and the need for charging infrastructure or hydrogen supply networks introduce new design and logistical considerations. In the context of a 16 m3 bed, these tradeoffs become especially nuanced: the unit must still deliver reliable peak torque to manage heavy loads, yet it should do so with a footprint and weight balance that keeps the vehicle agile enough for maneuvering in constrained spaces.

The materials science underpinning these trucks further reinforces their ability to perform under demanding conditions. The bed and related wear zones are made to resist abrasion and impact. A combination of high-strength steel and protective linings minimizes the rate at which the body corners wear away and the floor loses its geometry. The result is a chassis and body that can maintain its original capacity across thousands of loads. In cities and industrial sites that deal with moist or variable waste streams, the design must also account for corrosion resistance and washdown compatibility, ensuring the vehicle remains productive even after exposure to sludge, mud, or damp earth. These considerations are paired with thoughtful maintenance regimes—regular inspection of hinge pins and hydraulic lines, scheduled replacement of wear plates, and proactive checks of the bed mounting hardware—to sustain performance and uptime.

The field applications for a 16 m3 dump truck illuminate why this specific capacity resonates with operators across sectors. In mining and aggregate production, the vehicle supports rapid material movement from working faces to crushers or stockpiles, reducing the number of trips required and lowering unit costs. In road construction and earthworks, the truck’s cargo box enables a practical balance between payload and the ability to maneuver on site. Municipal and civil projects leverage similar strengths when transporting excavated soil, grit, or sludge from treatment or channel-cleaning operations. In all cases, the 16 m3 volume acts as a practical standard that aligns with typical loading patterns, site layouts, and the common sizes of hoppers and dump chutes encountered in field operations. The outcome is a vehicle that can complete a sequence of filled- bed cycles with predictable timing, allowing operators to plan logistics with a reliable cadence and simplify maintenance scheduling around shifts and project timelines.

Looking ahead, the 16 m3 class of dump trucks is poised to integrate cleaner propulsion and smarter operation without sacrificing the essential durability that field teams rely on. The move toward electrified and hydrogen-based powertrains is not just about compliance with tighter emissions rules; it reflects a broader aspiration to reduce fuel costs, lower noise in inhabited work sites, and ease maintenance burdens where on-site servicing can be challenging. The design philosophy that governs these machines—robust raw-materials selection, durable bed construction, resilient chassis, and adaptable drive configurations—remains the backbone of future iterations. As powertrains evolve, the critical challenges will center on energy density, weight management, and thermal performance, ensuring that the bed remains the limiting factor for payload—never a bottleneck caused by power or maneuverability.

In sum, the 16-cubic-meter dump truck embodies a compact, versatile, and rugged solution for heavy material transport. Its design emphasizes a harmonious blend of capacity, durability, and adaptability to diverse work environments. The vehicle’s ongoing evolution—toward lighter, smarter, and cleaner propulsion—will continue to redefine what is possible within this key segment of the heavy-truck landscape. For readers seeking a broader perspective on related heavy-duty configurations, see 16 Moving Truck.

External reading: https://www.energy.gov/eere/vehicles/articles/hydrogen-ICE-heavy-duty-trucks

16轮卡车的构造与运输能力:在极限重量下的工程艺术

16轮卡车并非一辆普通的运输车辆,它代表了一种在极端重量和复杂路况中仍能保持稳定与可控性的工程范式。想象一辆车身跨越宽阔的公路,承载着超出常规的货物体积与重量,车轮在每一次路面接触点都要承受巨大的压力。要让这样一台车在崎岖的坡道、湿滑的弯道、长距离的风雨环境中完成任务,设计者需要把重力、惯性、摩擦、热量与疲劳等因素共同纳入考量。这种综合性的工程决策,决定了16轮卡车的性能边界以及运营成本的高低。

在最核心的结构方面,三轴以上的六轴配置已成为最常见的选择之一。前桥通常承担转向与一部分载荷,后方的驱动桥组则承担大部分承载与牵引力。通过在前桥与后桥之间分布轮轴,设计者能够将载荷更均匀地传递到地面,降低单轴的应力集中,同时提高牵引力和制动性能。这种多轴布置带来的直接效果,是更高的载重能力和更低的地面压强,使得超重货物能够安全地从起点运送到终点。为了实现更高的承载效能,车架通常采用高强度钢材打造的箱形结构,并通过多根横向和纵向支撑梁来提升整体刚性。这样的框架不仅在静态承载时表现出色,在高强度的震动和曲线行驶中也能维持货物的稳定性,减少货物与车身之间的相对位移,从而降低货物受损的风险。

悬挂系统则是确保路面冲击被有效缓冲的关键部分。现代16轮卡车多采用空气悬挂或混合悬挂方案,能够根据载重自动调整车身高度,使货箱始终保持在最佳高度,从而减少货物在颠簸路面上的摇晃。空气悬挂还具备自适应自诊断功能,当某一边的载荷偏高时,系统会自动调节以维持水平姿态,提升行驶稳定性与转弯安全性。与之配套的轮端减振系统、减震块以及跨轴路径的优化设计共同作用,使高速行驶时的侧向稳定性显著提升。

传动系统在这类车辆中承担着起步与持续爬坡的双重任务。大排量、高扭矩的动力系统结合多挡变速箱,提供了从低速大扭矩起步到高速度平顺换挡的能力。为了应对重载工作状态,传动系统常采用分动机构、低速档和较宽的齿轮比区间,使得在极端坡道或湿滑路面上车辆都能维持良好的牵引力与控制响应。与发动机相配合的,是高效的传动控制系统,它能够在不牺牲稳定性的前提下,尽量减少换挡冲击与动力损失,使得整车在低速阶段的加速与中高速度阶段的巡航都保持线性、可控。

制动系统则是确保安全的另一道关键防线。电子稳定控制系统ESC、防抱死制动系统ABS以及先进的制动压力分配算法共同工作,在复杂路况下辅助驾驶员维持车道定位与方向稳定。对这样的大型车辆来说,制动响应不仅要足够迅速,更要具备良好的热稳定性,因为长距离运输和频繁制动会导致制动系统产生大量热量。电子监控与预测性维护的结合,使维修团队能够在异常信号出现之前介入,避免因制动失效而带来的严重后果。

重量与承载能力是评价16轮卡车的重要指标之一。由于多轴分布及强韧车架的组合,这类车辆的GCW往往达到甚至超过数十吨级别的上限。正因为如此,运营商需要对载荷分布进行严格管理,确保超大件货物在运输过程中的受力均匀,避免单一轴承受过大压力导致结构疲劳或局部变形。多轴设计还带来更灵活的货物配置,能够容纳大型工业设备、风力发电机组的部件、以及超重运输所需的特殊货箱或支架。

在实际运输任务中,16轮卡车表现出的不仅是力气,更是一种对复杂工程需求的响应能力。它们能穿越长距离运输中的各种路况,从高速公路的直线加速到山路的爬坡维持,从仓库到施工现场的短途转运,均需在精细的货物管理、路线规划与时间控制之间取得平衡。为了实现高效运行,现代化的运输体系还引入了智能监控与远程诊断。通过车载传感器、卫星定位与云端数据分析,运营团队可以实时了解车辆状态、轮胎磨损情况、载荷位置以及货物温控需求等信息。这种信息化管理在降低运输风险、提升准时性方面发挥着越来越重要的作用,也为日益严苛的行业合规要求提供了有力支撑。

值得注意的是,16轮卡车这一术语本身并非一个单一的车型标签,而是涵盖了多种高载重运输解决方案的共同特征。它既可以指拥有16个轮子的重型牵引车及其半挂车组合,也可能延伸到一些专用车辆的多轴配置,以及在特定应用场景中需要更复杂轴系的超重运输设备。因此,理解其构造与运输能力时,必须将具体的载荷类型、路面条件、法规限制以及任务周期等因素放在同一框架内考量。对于行业从业者而言,掌握这些综合因素,才能在确保安全与合规的前提下,最大化运输效率与成本效益。

如果你在实际场景中需要对比不同的多轴运输方案,或者希望了解在日常供应链中如何更好地调度与配置这类车辆,关于16移动卡车的进一步讨论可以在内部资源中找到参考。请查阅这篇文章以获得更具体的操作视角:16 moving truck。

外部参考资料也提供了更深入的工程分析,尤其是在结构设计、载荷分布与运输性能评估方面的学术研究。相关的权威论文对重型多轴卡车在不同载荷状态下的安全性与效率做了系统阐述,可以帮助工程师将理论与实际操作结合起来,以提升未来设计的鲁棒性。相关外部来源:https://www.sciencedirect.com/science/article/pii/S187770562400012X

沉浸在虚拟公路上的真实驾控:卡车模拟16如何塑造驾驶体验

在探讨“16 truck”这一广义术语的浮现形态时,卡车模拟16并不仅仅被视作一种娱乐产品,而是一扇通向现实驾驶世界的观察窗口。它以高度的沉浸感和细致的物理反馈,拉近了玩家与真实大货车驾控之间的距离。游戏采用第一人称视角,让玩家的视线、仪表信息和操作反馈共同构成一个近乎一比一的驾驶场景。车型的差异、油门与制动的敏感性、档位切换的节奏,以及转弯、倒车时对距离和角度的精准控制,所有这些要素拼接在一起,形成一种“被看见的真实”,让玩家在虚拟世界里经受与真实司机类似的压力测试与决策挑战。正是在这样的高度还原中,驱动体验从单纯的复制,逐渐升华为一种需要判断、预判和即时反应的综合能力训练。

在具体的游戏机制层面,驾驶体验的真实感来自于对车辆动态的细致建模。玩家不是在松散的谜局里试错,而是在连续的操作回馈中感知车辆的重量、惯性和轮胎与路面的交互。踩下油门,车身的前倾、轮胎的抓地力变化、以及与地面摩擦系数的微妙平衡,都会被清晰地传达给玩家的手部和潜意识层面。刹车系统的响应也不再只是“变速按钮的节奏”,而是有着明显滞后与前后制动力分布的真实感——这要求玩家在紧张场景中保持对距离、速度和侧向偏差的统一控制。若把握得好,玩家会体会到一种来自驾驶舱的成就感:在复杂道路和严格限速下完成任务时的那份自信,仿佛自己已经成为一个真正的驾驶者。

游戏中的九款高度仿真卡车覆盖了从城际运输到长途干线的多样场景。它们各自拥有独特的性能参数与操控特性,促使玩家在任务之间不断调整策略与技术。不同车型带来的重量分布、转向半径、发动机响应时间,以及载荷与空气动力效应的变化,迫使玩家用不同的驾驶路径和节奏去应对。这样的设计不仅拓宽了玩家对重型车辆的认知,也强化了对载荷安全与运输效率之间平衡的理解。与此同时,游戏还引入了多种货物拖车与运输任务,让玩家在单一模板中体验不同运输情境,感受与现实工作相似的调度和任务管理过程。

地图与路网设计是另一个强化代入感的核心。中欧与西欧的公路网络被刻画得相对完整,沿途穿插有二十多个城市的地标与风景,标志牌、限速规定、交叉路口的交通规则等细节都被纳入到日常的驾驶循环中。玩家不仅要掌握油门与刹车的基本操控,还要学会在城市交通、乡村公路甚至货运专线之间灵活切换。道路的坡度、气候条件、路面磨损程度,都会影响载重车的稳定性与能耗,这些因素共同决定了路线选择与时间管理的策略。正是在这种“现实约束+任务目标”的叠加下,玩家的路线规划能力、风险评估能力以及对突发状况的应对能力得到自然锻炼。倒车、掉头、并线等高难度场景的模拟尤为考验手眼协调与空间想象力。

从教育与训练的角度看,卡车模拟16提供了一种低成本、可重复且可控的训练环境。对于那些希望理解重型货车操作要点、提升反应速度和路况判断力的玩家而言,游戏成为一种视觉与操作预演工具。它能够在虚拟环境中重现大量真实世界中的典型场景,如限速严格、转弯半径受限、载荷影响车身稳定性变化等。通过不断的练习,玩家能够建立起对“何时加速、何时刹车、何时换挡”的直觉,这种直觉在未来现实驾驶的培训或资质考试中往往十分受益。需要强调的是,虚拟与现实之间存在差距,游戏的目标并非替代训练,而是作为提示、练习与情境熟悉的有效补充。

在体验的节奏和情感维度上,沉浸感还来自于对环境和规则的遵循。玩家不仅要处理机械的操控,还要遵守路网的交通规则、信号灯、限速标志等社会化规范。这种多维度的规则遵循不但测试了驾驶技能,还考验了情境判断与耐心。更重要的是,沉浸感并非来自单点的“真”,而是来自多点的协调:仪表盘的灯光、方向盘的阻力感、交通参与者的反应、路面的微妙震动,以及背景音乐与环境声效共同构成的完整感官体验。即使移动端在画质和方向盘力感方面有局限,整体的流畅性和操作逻辑仍然确保了高水平的驾驶模拟体验。对于那些想要在非正式环境中理解重型货车驾驶的人群,这种体验提供了一个安全而真实的前置感知。

在扩展层面,卡车模拟16与现实世界的联系在于它让玩家更敏感地理解“16 truck”这一范畴所包含的多样性。不同的车辆形态、不同的任务需求,以及不同的路况约束,共同构成一个关于运输、效率与安全的学习系统。对整个行业生态而言,这类高质量的模拟产品提供了一种新型的认知资源:它帮助公众更好地理解重载运输背后的复杂性,也为未来在教育、培训与职业发展层面的创新应用奠定了基础。若你愿意进一步探索与“16 truck”相关的实践内容,可以查看16-moving-truck指南以获取更具体的内容与实践要点。

在总结层面,卡车模拟16并非单纯的游戏体验,而是一种以现实为镜子的学习工具。它通过真实的物理反馈、丰富的车型设计和复杂路况的综合呈现,帮助玩家在娱乐中建立对大件运输的深刻理解。尽管某些细节仍有局限,尤其在移动端的硬件适配方面,但其对驾驶沉浸感和操作真实度的提升,是对未来培训工具形态的一次有力示范。对于关注“16 truck”这一主题的读者而言,这款游戏既提供了直观的体验,也引发了关于现实世界驾驶教育与虚拟仿真结合的更广泛讨论。

外部参考: https://www.3dmgame.com/youxi/2025/1021/478919.html

16米低平板半挂车:从结构曲线到现场运载的全景解读

在现代大型运输与工程作业的渐进式复杂性中,16米低平板半挂车以其独特的结构与高度定制化的载荷适配,成为连接设计单位、制造现场与施工场地的关键纽带。这一载具并非单一的车型标签,而是对“超大件运输”这一领域的高度专业化回答。它将超长、超重的设备安全地从工厂、港区或矿区送往公路网密布的现场,履带式挖掘机、轨道设备、发电厂的重型设备,以及钢材与罐体等大型货物,都需要其强韧的承载力与对路况的高适应性。这种能力背后,是系统性的工程学设计、严格的制造工艺,以及对路上法规边界的精准把控。正是在这个叙事中,16米低平板半挂车成为理解“16 truck”这一广义话题的重要节点,它把工程、物流与法规的关系紧密地串联起来。\

在具体的技术指标上,长度定在16米这一基础尺度之上,宽度则可达到3米这一极限宽度——这是需要超限许可才可能实现的边界值。货台承载面的离地高度通常落在0.9到1.2米之间,这一高度区间的设定并非偶然,而是为了在装卸作业时兼顾稳定性与可操作性。更深的结构学意义在于车架的阶梯型箱形截面,这种设计通过高强度合金钢实现强度与韧性之间的平衡。纵梁多采用工字形截面,增强整体刚度,确保在跨越不平路面和起伏路段时,货物负载不会在关键节点上产生不必要的应力集中。\

驱动与轮轴配置的选择,直接关系到这类车辆在多样路况中的操控性与承载均衡。最常见的组合是六轴线设计,形成三线六轴的结构布置,整车共计24个轮胎,分布在六个独立的车轴上。这种安排极大地降低了单位轮胎载荷,提升了对路面压力的分散度,并在需要时提供更好的牵引力与稳定性。单胎在低速状态下的载荷承受能力大致在4吨级别,这也解释了六轴设计在重载运输中的应用价值。对于动力形式,六×四(6×4)驱动更常见,它以较强的牵引力和较好的燃油经济性,平衡了长途运输的成本与作业时的响应性。与之配套的,是先进的制动系统与液压全自动转向系统,这些都是在复杂路况、需要精确操控的场景中不可或缺的安全保障。\

货台的低平设计是该类别车辆的核心优势之一。低台高度搭配较大的货物尺寸,使得装卸作业的难度显著降低,同时也有助于维持较低的重心,从而降低横向摆动和侧风影响对整车稳定性的冲击。这对于需要快速装卸的大件设备尤为重要,比如需要在工地现场通过大型起重机进行就位的重型机械,或是在电站现场安放的罐体与大型部件。正因如此,16米低平板半挂车在运输不可拆解的大型设备时,常被选作首选方案。\

在载荷与结构的结合方面,货台承载面的设计并非单纯的容量数值,而是要与货物的形状、尺寸和重心位置共同协调。货物在货台上的放置必须遵循“跨轴分布、对称加载、尽量靠近中线”的原则,以避免因不均匀载荷造成的车架疲劳与行驶过程中的不稳定性。对那些需要跨越铁路轨道、穿越工业园区或沿海公路网的运输任务,架设在货台下方的支撑点和横向稳定件也需要与车体结构接口紧密匹配,以确保在路段切换时的平顺过渡。\

法规与合规性是理解16米低平板半挂车不可回避的维度。当前的总质量上限通常被设定为约49吨,装载后货高不得超过4米,某些特殊许可情况下才可能扩大到约4.5米的高度。值得注意的是,历史上曾出现过对更长版本低平板半挂车的注册限制与取消情况的讨论,但在16米这一长度范围内,这类车型仍被广泛应用于合法运输场景,享有较为明确的技术规范与监管框架。对运营方来说,这意味着需要在出 cargoh7 routes 之前进行周密的路线评估、对车辆与载荷的二次检查、以及对高度、宽度、重量等极限条件的严格把控。对于宽度,超过3米的运载通常需要专门的许可与前导车辆,确保在公路网络中遇到拐弯、桥梁和隧道时的通行可控性。\

这些法规并非空洞的约束,而是与实际运输需求形成互动的设计参数。正因如此,载货设备的选择往往与现场的工艺流程密切相关。比如,运输重型机械或轨道设备时,低平板的超低托载台有助于在工厂到现场的过渡阶段减少装卸设备的工作量;在能源项目中,像大型罐体、发电设备或钢材的运输,要求货物在装载前就已在货台上实现了近似理想的重心分布,以避免在高速公路或市区路网中的切换与制动带来额外的安全风险。\

在实际作业的操作层面,路线与时效的管理也会被“16米低平板半挂车”的特性所影响。因为车辆的尺寸与自重使得某些城际路网、桥梁结构或隧道高度限制成为需要提前评估的重要环节。为此,行业内部常把这类运输任务视为一个组合式工程:前期的路线勘察与许可申请、现场协同的起重与装卸方案、以及对到达时点的精确调度,构成了整个运输计划的核心。为了扩展行业认知并提供更多实践参考,相关物流社区中也会讨论与“16 Moving Truck”相关的场景与经验,帮助从业人员跨越理论与现场的鸿沟,从而在现实中实现更高效的运载。点击此处了解更多关于16 Moving Truck的行业讨论与案例分析。 https://larentaltrucks.com/blog/16-moving-truck/

从更宏观的视角看,16米低平板半挂车的存在也映射出物流体系对“大件运输”能力的持续追求。它要求制造方在材料科技、焊接工艺、车架结构与整车控制系统之间建立更高水平的协同,以确保在高应力与长距离运输中的可靠性。它也要求运输方在合规、维护、保险与现场管理上形成完整的闭环,确保在多变的路况、不同的地形以及各种气象条件下都能够稳定运行。对于正处于成长阶段的物流领域而言,16米低平板半挂车不仅是一个“载具”的存在,更是对系统性工程能力的考验与示范。\

在阐释这一技术篇章的同时,不难发现,16米低平板半挂车与其他“16 truck”类别之间的关系其实是互补而非对立:前者强调的是载荷的超大尺寸与低重心设计,后者则涵盖了从自卸车到仿真游戏中的虚拟载具等广泛场景。它们共同构成了一个多层次的生态系统,其中每一类都在特定的工作场景中提供独到的解决方案。为了保持叙述的连贯性,后续章节将继续追踪不同类型载具在实际工程中的应用案例与设计演化,帮助读者理解从单一车型到整套运输系统的转变过程。\

外部参考: 若需要对超限运输的法规背景进行深入了解,可以参考官方交通运输部门关于超限/超载运输许可与路线评估的公开指南与资源,帮助读者把握跨区域运输的合规性与实操要点。 https://ops.fhwa.dot.gov/freight/publications/oversize/

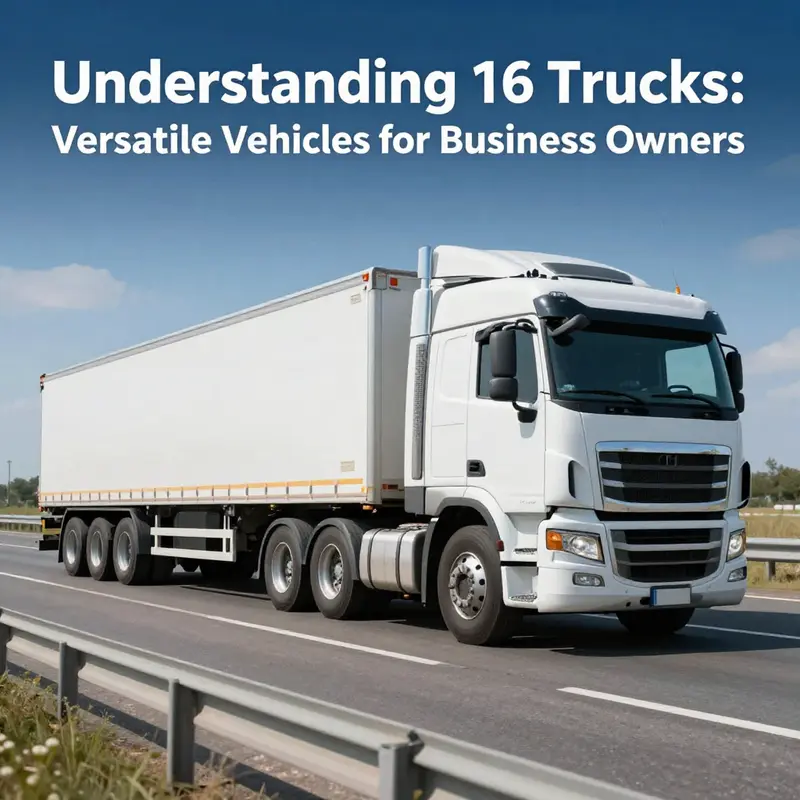

长而稳、贯通供给链的16米卡车:现代物流的核心载体与未来趋势

在现代物流的广阔场景中,16米卡车并非一个单一的车型标签,而是一组能够应对不同任务的承载平台。它的核心价值在于把大件货物一次性运到位,减少中转、减少装卸次数,从而缩短周期、降低损耗、提升运输的可预测性。对于建筑材料、钢材、机械设备乃至超长木材等货物,16米的长度提供了长排布的载货平台,使得货物可以排布得更整齐、受力更均匀,运输过程中的稳定性更高。这样的稳定性不仅来自货台本身的结构设计,也来自对载荷分布、牵引与制动系统的综合优化。只有在整车与路况之间实现高水平的一体化,才可能真正把“一次性运输多货、减少中转环节”的优势转化为可落地的成本收益。

Final thoughts

As the logistics industry continues to evolve, 16 trucks play an increasingly vital role in meeting the demands of various sectors. Their diverse applications, ranging from construction to long-distance transportation, underscore the necessity for business owners to grasp their capabilities. By understanding the unique features of 16 trucks, businesses can optimize their logistics strategies, ensuring efficient and responsive supply chain operations. Embracing these vehicles within transportation fleets not only enhances operational efficiency but also positions businesses strategically for future growth and competitiveness.